No matter what kind of knife or sharp tool you are using, constant sharpening is required to keep it in tip-top shape. This is why everyone, from beginner knife enthusiasts to the highly experienced, should look into finding the best sharpening system that suits their purposes to keep their knives sharp and safe. With so many options in the market, the choice can be overwhelming. In this case, you can feel free to buy any that suits your work from the list I reviewed below.

What Are the Best Knife Sharpening Systems?

- Work Sharp Knife & Tool Guided Sharpener System

- Lansky Deluxe 5-Stone Sharpening System

- Edge Pro Apex 4 Knife Sharpening System

- Work Sharp Knife & Tool Sharpener Ken Onion Edition

- KME Precision Manual Knife Sharpener System

- Wicked Edge Pro Pack 1 Guided Knife Sharpening System

- Wicked Edge GO – Precision Knife Sharpener

- Edge Pro Apex 3 Knife Sharpener with Bag and Kit

- Tormek T4 Water Cooled Precision Sharpening System

- Wicked Edge Gen 3 Pro – Precision Knife Sharpener

Review of the 10 Best Knife Sharpening Systems in the World

1. Work Sharp Knife & Tool Sharpener – Top Knife Sharpening System

This USA-made Work Sharp Sharpener holds the capability to supply precision honing guides for scissors, kitchen knives, hunting knives, folding knives, serrated edges, gut hooks blades, and partially serrated tactical knives. The system consists of easily adjustable sharpening grit bands. The premium grinding sashes satisfy all of your sharpening requirements. This appliance carries a 6-foot tall power cord for easy mobility and correspondingly includes three sorts of premium abrasive belts (P80-coarse, P220-medium, and 6000-fine). Also, they will not burn or harm the steel of the blade during working.

The kitchen knife model grinds the blades at an angle of 40 degrees, and the outdoor knife design sharpens blades to a 50-degree angle. The adjustable precise angle range (15° – 30°) allows the easy functioning of the tool. The knife sharpening system can also be practiced to sharpen a large-scale of bladed store accessories and yard and backyard appliances such as Garden Pruners, Lawn Mower blades, shovels, shears, scrappers, and many more. Furthermore, an instruction guide and a DVD are boxed to allow easy access to the consumers.

The Work Sharp Knife & Tool Sharpener can carry out 110v power source activities conveniently. However, power converters for 220v are strictly restricted from being used. The respective equipment can be worked with a 12v power inverter from the truck, boat, car, etc. Providing a 1-year warranty against defects, the sharpener is undoubtedly one of my top pics.

2. Lansky Deluxe 5-Stone Sharpening System

Lenski Deluxe knife sharpening system is an entire community for sharpening accessories of the kitchen knives, outdoor knives, sporting knives, yard knives, and many more. This USA-made item provides professional results to the blades of your sharpening tools like no one else. The system approaches with a compact package that includes knife clamp, knife clamp screws, guide rods, honing oil, a decent carrying case, and useful guidelines.

It consists of extra-long knife clip bolts for holding heavier and thicker edges. This clamp operates the knife at a steady posture and allows the angle guide to present the greatest angle (17-degree, 20-degree 25-degree, and 30-degree angle choices) with every single cuff of the sharpener. To complete edge cuttings and subsistence, the ultra-fine hones administer perfect grit. Honing oil is also specially formulated and included in the package for better sharpening. This sharpening system provides outstanding angle ranges for the user to pick the best suitable sharpening edges for their accessory. A storage kit is attached that comes in handy to secure all the accessible components at the same place.

The five-stone (extra coarse black hone 70 grit, coarse red hone 120 grit, medium green hone 280 grit, fine blue hone 600 grit, ultra-fine ceramic yellow hone 1000 grit) sharpening system is a desirable element because of its superb clamp installments, extremely sharp performance, and the collection of explicit angles to implement the perfect edge to sharpen your tools. From the field to your kitchen, to the store, it accomplishes all the sharpening of any sort of blades perfectly. Both beginners and professionals can simply be habituated with this appliance.

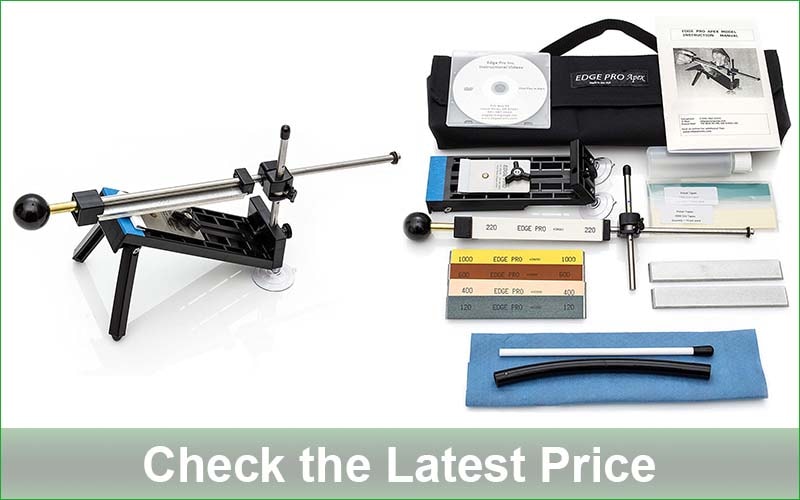

3. Edge Pro Apex 4 Knife Sharpening System

Having all the necessary sharpening tools included in the package, Edge Pro Apex 4 Sharpening System takes only a small place to perform the tasks, and it is lightweight (only 2.9 pounds) enough to carry. It allows you to adjust too many different angles suitable for perfect sharpening.

The Apex series has 4 models, and among them, the Apex 4 has the most necessary stones and tapes in the kit. The product comes with 5 water stones, starting from 120 grit up to 1000 grit Ultra-fine water stone. The two packs of polish tapes have 2000 grit in one of them and 3000 grit in the other. Fifteen of them are included per pack. A 1200 grit ceramic hone, which is 8 inches long, allows easy control.

The black Cordura carrying case lets you organize the tools properly before storing or transferring. The material chosen for the body parts is ceramic which makes it durable.

4. Work Sharp Knife & Tool Sharpener Ken Onion Edition

Work Sharp Knife & Tool Sharpener is portable and has trigger phases to give you easy control over the sharpening process. It runs on electricity with a 1.5 ampere AC. It takes 120 Volt to operate. It is easy to store with its light bodyweight. It comes in white and black.

The sharpener offers various angles to hold the sharpening tool that ranges from 15-degree to 30-degree. Also, this best knife sharpening system includes a variable motor to control the grinding speed, which allows slow hone or fast grinding. Its sharpening tool is shaped perfectly for sharping from the outdoor knife to kitchen blade and even axes. Synthetics were used to build the body components.

The sharping system comes with different coarse belts that include X65 Coarse abrasive belt, P120 Extra-coarse belt, X4 Fine abrasive belt, X22 Medium abrasive belt, and 6000 Extra-fine abrasive belts, an initial guide, and a detailed manual. A 1-year warranty is offered for workmanship and design issues that are only for consumer use and not for industrial uses.

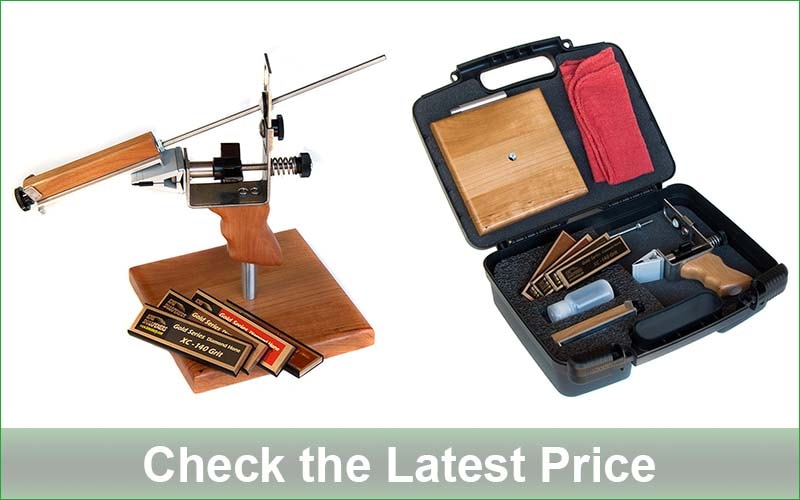

5. KME Precision Knife Sharpener System with 4 Gold Series Diamond Hones – Base Included

Considering everything you want, the KME Precision Knife Sharpener System comes with all that you will require in your sharpening process. The tiny size makes it easy to transport and store. It is also portable. One of them is the rotating blade clasp that can deliver a faster sharpening. Another one is the spherical rod guiding structure that can ensure the angles are accurate.

You can assemble the angle of the sharpener by adjusting it within 17 to 30-degree. It is quite easy to adjust them with the help of the marked-out degree. It is possible to swap the premium vise with either the broadhead sharpening jaws or the KME pen knife. You can purchase them separately. With the stable cherry wood-built parts, the grip and the stone holder can provide easy handling. All of the tools used for sharpening are screwed perfectly to one guide rod. All of these stay inside a steady container to carry them that has a perfect size. It is also properly protected from both sides.

The clamp is lined with neoprene that avoids any sort of scratching and is assisted with depth lines to rearrange the knife. This is an American-made knife sharpening system that comes in 4 KME gold series diamond hone grits, which are XC 140, C 300, F 600, and XF 1500. It can be used in any type of workplace.

6. Wicked Edge Pro Pack 1 Knife Sharpening System with Quartz Stone Base

Wicked Edge Pro Pack 1 includes all the accessories that you will need in your work. It has a perfectly improved premium quality quartz stone base; you won’t need to buy them separately. The base comes in different colors.

The latest ball-joint guide rod system is included in the system that allows you to sharpen your knife without any errors to give it a solid and firm quality. A sharpener of great quality was properly screwed to the base that lets you adjust it from 15 to 30-degree. This amazing system can sharpen your knife up to 17 inches. The sharpening process is faster when you use this sharpener. It can hold any blade up to a thickness of 3/8 inches.

Wicked Edge Pro Pack 1 comes with 2 stones, with both of them having 100, 200, 400, 600, 800, and 1000 grit and a micron strop (3.5/5) with a grit of 4000 or 8000. A detailed guide is added to the package. The system is proudly made in the USA.

7. Wicked Edge GO – Precision Knife Sharpener – with Standard Bag

The Wicked Edge Go is a complete set of tools for sharpening a knife to the angle desired. It is made in the USA. It can sharpen any type of knife so quickly yet so smoothly. It is possible to easily position the knives and repeat the sharpening process with the knife’s soft touch-ups.

The angles are marked to 15 degrees for a knife with an edge of 5/8 of an inch. The whole system is lightweight, allowing fast transportation. It is portable and takes a tiny space, so it is easy to store. You get an additional storage bag to arrange the tools properly before storing it. Abrasive papers are also included in the package.

All of the body components are created from aluminum and steel, making them highly durable. It has a diamond stone pack of medium (200 grit) and coarse (fine 600 grit). It is easy to mount it with the C-Clamp mounting and holed platforms, allowing you to mount it on any hard surface. The system can be arranged for both right-hand users and left-hand users.

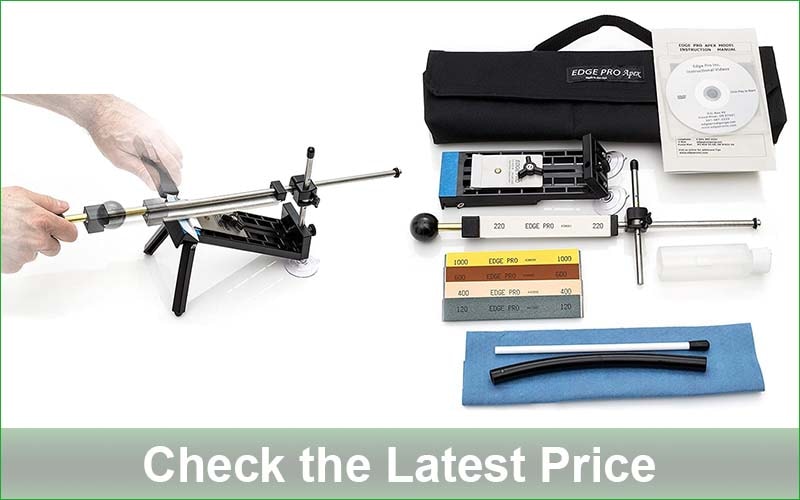

8. Edge Pro Apex 3 Knife Sharpener – with Bag and Kit

When it comes to the best knife sharpening systems, the Edge Pro kits are some of the best ones, and Apex 3 is nothing less! The ability to sharpen serrated blades and knives up to 3.5” wide is its peculiarity. It provides different sharpening angle options starting from 10 up to 24 degrees. The water stones can be easily changed by a knob as they are mounted on plates. Moreover, its compactness is another reason why many knife experts prefer it over newer sharpening tools. It is perfect for sharpening at a constant angle.

The kit comes with five kinds of water stones for perfect sharpening. From the usual 120 grit coarse to 1000 grit ultra-fine stone. It can sharp the hardest of steels like S30v, El Max, S35V. And even if you are not experienced with knife sharpening, you can easily get razor-sharp edges on your knives with the Edge Pro Apex 3 due to its simplicity.

Portability is ensured as the kit is provided with a durable case. The instruction manual, DVD, water bottle – these also come with the package. Made in the USA, this manual and straightforward sharpening kit could be an excellent investment without a doubt.

9.Tormek T4 Water Cooled Precision Sharpening System with 8-Inch Stone

Bringing considerable improvements, the T4 sharpening system is significantly better than Tormek’s T3. The 200mm grinding wheel takes traditional sharpening to a new level. The 120-watt motor attached to the T4 provides continuous power for faster sharpening. Having the top made of die-cast zinc and a body of high-quality ABS plastic that is impact resistant, the material choice for the T4 is admirable.

You are able to sharpen pretty much every with it, starting from plane irons, wood chisels, carving tools, knives, axes, etc. The sharpening stone is dual grit and rotates at 120 RPM, enough to sharpen your knives while not causing overheating or damage. With 19 pounds weight, the T4 is much lighter than T7, thus being easier to relocate whenever you want!

The package comes with required accessories like a leather honing wheel, grindstone, angle master, stone grader, and a manual. Both heavy and light grinding is possible with the T4, while the T7 was limited for larger tools. Made in Sweden, this item comes with seven years of warranty. Considering all these factors, the T4 is a flawless grinding tool.

10. Wicked Edge Gen 3 Pro – Precision Knife Sharpener – with Carrying Case

By bringing clamping blades’ one-step adjustment, the Wicked Edge Gen 3 Pro is a stand-out product compared to the brand’s other sharpening tools. A spring attached clamp ensures a strong grip and keeps the knife centered while you sharpen it using the exceptional stone packs provided with the package – for example, 100, 200, 400, 600, 800, 1000 grit 6 diamond stones pack! The rapid angle adjustment mechanism is excellent for precise sharpening, as you can adjust knives correctly, by just pulling a lever.

With this system, I was able to sharpen my 15″ long blade without needing any extra tools. I love the angle range of 13.5 to 27.5 degrees (27 to 55 degrees inclusive) which allows me to sharp with precision. The best part about the sharpening system is its allowance of micro-angle adjustment of as low as 0.05 degrees. As a result, there is no doubt that all kinds of professional and home users can use this tool! And no matter how thick your knives are, you can always use the tension adjustment mechanism to mount your blade correctly.

Item dimensions LxWxH = 7″ x 4″ x 4″ and weighing only 0.31 Pounds / 4.96 ounces, this lightweight compact tool is an excellent choice for anyone who needs a simple knife sharpening system. It comes with a durable case for carrying and has a limited lifetime warranty against all kinds of defects in craftsmanship.

How to Choose the Best Knife Sharpening System – Buying Guide

A knife sharpening system means more than maximizing the lifetime value of your knives. A dull blade can be frustrating to use, and even dangerous to the uncareful. Accidents can happen when a dull blade glides off whatever you’re cutting and onto things that are not meant to be cut. A dull knife requires greater force to cut with and lacks control, which makes it prone to mishaps. For all these reasons you need to find the right sharpener system from the market. By considering the following guidelines, you can make the most informed decision about choosing the best-rated knife sharpening system.

First, of All, What are You Trying to Sharpen?

To determine what features are necessary for your sharpening system, understand what types of knives you plan to sharpen.

Ask yourself; will you use your system to maintain kitchen knives, scissors, hunting knives, tactical folding knives, serrated edges, survival bowie knives, gut hooks blades, or prized fillet knives?

How about your backyard appliances such as garden pruners, lawnmower blades, shovels, scrappers, shears, and many more.

Even better, how about all of the above? Exploring these questions will eliminate certain systems that do not suit your needs, narrowing down your search.

What Types of Knife Sharpening Systems Exist?

It can be summarized into several main categories, here I try to describe some of the most popular knife sharpening systems that exist at the present time.

1. Stone Sharpening System

Perhaps the most common and most ancient form of knife sharpening. A sharpening stone sharpens a blade by grinding it to give it a sharp edge. Sharpening stones come in many shapes and sizes but are most commonly found in the form of a flat block of dense material. They are made of different materials such as stone, ceramic, diamond, and there are some made with artificial materials as well. Some require oil, others require water, while there are also stones that do not require any lubricant at all.

Stone sharpening is one of the most efficient ways to sharpen your knife. It is fast and also versatile because you can use your sharpening stone to sharpen many different tools at different angles. Sharpening stones can also last quite a long time. However, sharpening a knife using a sharpening stone is a skill that requires a steady hand and much practice. The angle of the blade, the direction, and the movement are all factors that can influence how well-sharpened your blade is on the best stone sharpening system.

One important thing you should remember is that a sharpening stone is only useful for sharpening straight-edged blades. If you try to sharpen a serrated knife on a flat sharpening stone, the serrated knife will lose its serrated edges.

2. Electric or Guided Knife Sharpening System

These sharpeners are the easiest and fastest to use, and suitable for all skill levels as they feature guided slots to place dulled blades. They usually involve two or three steps, where the first slot uses a coarse grit to sharpen dull blades while finer grits work in the later stages to hone the blade.

However, they tend to be more expensive with certain models reaching up to $100, are not portable for purposes such as a camping trip, and may not sharpen the entire edge. Since they often employ spinning sharpening stones or abrasive belts, they are ill-suited for serrated knives and may damage them.

3. Handheld or Manual Knife Sharpening System

If you are more than a sharpening novice, a manual or handheld sharpener is ideal as they are more affordable, compact, and helps achieve precise beveling, such as achieving razor-sharp edges. Their portability makes them the choice sharpener for traveling or fishing.

Depending on the type of manual knife sharpening system, there are two ways to use them – the system either lies flat on a surface while the knife slides through its slot, or the knife is placed spine-down while the sharpener is drawn down the blade. Similar to electric sharpeners, however, they are ill-suited for serrated knives and may cause damage.

4. Sharpening Steel System

Sharpening steel, also known as honing steel, is a handheld metal rod used to realign the edge of a blade. There is a common misconception that sharpening steel will “sharpen” a blade, however, a sharpening steel does not actually “sharpen” since it doesn’t remove any metal from the blade.

What it does instead is hone and realign the blade if there is a curled edge. The act of using sharpening steel is called “steeling”. Steeling can be done every day because it removes very little metal, while in contrast, sharpening a knife is done much less often. Some disadvantages of sharpening steel are that it cannot sharpen a dull blade nor can it remove nicks on the edge.

5. Pull-Through Sharpener System

To use a pull-through sharpener, you pull your knife through a V-shaped notch to sharpen the edge of your knife to a certain set angle. The slot is usually made out of two pieces of hard material such as carbide or diamond. Pull-through sharpeners are quite easy to use by simply placing the knife’s edge in the slot and pulling steadily from heel to tip with a light and even amount of pressure. They are portable, fast, and easy to carry around.

Some can be used to sharpen smooth blades as well as serrated ones. There are electric ones as well as manual, handheld versions. Some pull-through sharpeners have only one slot while others have two or three of decreasing coarseness to finely hone the blade. While the pull-through sharpener is cost-friendly and easy to use, disadvantages of the pull-through sharpener include scraping off metal very easily, meaning that frequent use will eat away your blade, and providing an edge of slightly lower quality compared to a sharpening stone.

6. Serrated Knife Sharpening System

Sharpening a serrated knife is not easy. Standard sharpening stones cannot be used to sharpen serrated blades, otherwise, the blade will lose its serrated edge. A handheld serrated knife sharpener looks like a thin metal rod that tapers towards the end. There are round rods as well as triangular rods for different types of serrations. By sliding the handheld knife sharpener back and forth at the serrations at the proper size and angle, it can hone the entire curve of each serration on a knife.

While sharpening a knife with a serrated blade takes a bit of time and effort, luckily, serrated blades typically don’t require sharpening as often as straight-edged blades do. A handheld serrated knife sharpener works well on serrated knives with single bevels, however, it does not work on scalloped or wavy edges, nor does it work on double serrated edges.

7. Crock Stick Sharpener System

A crock stick sharpener, also known as a ceramic rod sharpener, is a set of ceramic rods held in a V-shape at a predetermined angle. The blade is brought down vertically against the rods in a slicing motion, allowing the edges of the knife to be sharpened at a fixed angle. Crock stick sharpeners come in many different kinds. There are round rods for straight-edged knives and triangular rods for serrated knives.

The rods also have varying degrees of coarseness to sharpen and hone your knife to the finest degree. Some crock stick sharpeners have bases that allow the user to adjust the angle, while others do not. It takes a bit of time to learn how to use a crock stick sharpener, but it is easier than most other options.

What Kind of Best Knife Sharpening System are You Looking for?

The sharpening systems vary in sophistication and cost. In general, you want a system that is versatile and sharpens a variety of knives, includes different blade angles, and will not temper or warp the steel blade. Beyond those qualities, understand the types of knives you use, your budget, your expertise level in sharpening knives, and how particular you are about cut quality. Knowing these particulars will further refine your search for the best system that suits your needs.

What is Grit and Why Does It Matter?

Many standard sharpening systems, such as sharpening stones, electric sharpeners, and manual sharpeners, use stones to sharpen knives. Accordingly, the stone’s abrasiveness, called grit, is useful to know when selecting the best sharpening system for you. Specifically, grit size alludes to the stone’s particle density and is measured in microns; the higher the number, the smaller the particles and the finer the sharpening.

For general maintenance such as maintaining dull knives, a grit between 1,000 and 6,000 will suffice. A lower grit number will achieve desired bevel shapes quickly, but if you want a finer edge for something like a Japanese sushi knife, you will want finer grits, which cut slower and do not remove as much of the blade. When selecting a sharpening system, ensure that the grit or set of grits is appropriate for your knives and desired bevel shape.

What Blade Angles Should a System Include?

Manual and electric sharpening systems typically feature precision guides to ensure that your knives are sharpened to specific angles. Novices should look for a tool that allows for a specific set of blade angles that can handle a variety of knives, while more initiated users should look for systems with sharpening angles that closely align with their specific knives. More experienced users can also opt for sharpening stones or steels instead of a manual or electric knife sharpening system, as stones and steels yield greater control.

Wider blade angles like 45⁰ are appropriate for strong blades used for chopping, such as a cleaver. Meanwhile, wide angles between 25⁰ to 30⁰ degrees are ideal for sharpening outdoor utility or fixed blade knives, while kitchen knives sit at 20⁰ delivering a balance of sharpness and blade strength. Furthermore, a 15⁰ angle is ideal for a fine slicing knife such as a fillet, paring, or Japanise gyuto knife. With so many angle options, find a system that fits the knife angles you plan to sharpen.

What Bevel Shape Should a Sharpening System Accommodate?

If considering a manual or electric knife sharpening system, you should find one that maintains or achieves your desired bevel shape. As a quick refresher, bevel refers to the angle running up the edge of the knife and ranges from a rounded convex shape to more angular shapes such as a chisel or saber. Knives may be single or double bevel, so it is critical to find a system that will accommodate your various knife types. Of course, this concern does not affect sharpening stones and steels, as they offer users more control in the sharpening process.

Is the System Ease-of-Use?

How often do you use your EDC knife? How much time are you willing to spend sharpening your knife? If you are willing to put in the time and effort to learn how to manually sharpen your knife, then you might consider buying a sharpening stone or a crock stick sharpener to get the best results from a manually sharpened blade.

On the other hand, if you only wish to acquire a knife sharpener that is fast and easy to use, then you should consider buying a pull-through sharpener or even an electric one for the fastest and most efficient results.

What Is the Portability of the Knife Sharpening System?

When and where do you use your knife? If you often take your knife outdoors and go hunting or camping in the wild, a portable knife sharpener such as the pull-through sharpener would be the ideal choice because it is small, lightweight, and easy to use, so that keeping your knife sharp won’t be too much of a hassle in the great outdoors.

There are many best portable knife sharpening systems that include a combination of both sharpening rods and pull-through sharpeners that can fit right in your pocket as you trek out into the wild.

If, however, you prefer to stay at home, then the slightly bulkier knife sharpeners would work as well. Especially if you have many knives as well as other utensils around the house that need to be sharpened, then a sharpening stone would be perfectly suited for a variety of different tools.

How Much Time and Money are You Willing to Put into Sharpening Your Knife?

Buying a knife sharpener is an investment. A good knife sharpening system can be used to keep your knives sharp for many years while buying a low-quality one will take up your time and possibly ruin your blade. Electric sharpening systems tend to be on the expensive side, however, they are typically easier to use and sharpens faster. Electric sharpeners also require a power outlet nearby, therefore they may not be the ideal choice if you need to sharpen your military knives, hunting knives, or the tactical knives in the wild (although they are useful for kitchen knives).

Sharpening stones tend to be the most durable out of the aforementioned types of knife sharpeners, however, they can be quite costly. Before choosing a sharpener system, think about your budget and how much you are willing to spend in maintaining your knife at a high functionality. Very often, there is a trade-off between price and quality. For those on a low budget, the pull-through sharpener, as well as other small, handheld sharpeners, give you a decent quality edge for a modest price.

What Safety Measures Do You Need?

Depending on your comfort and experience with using sharpeners, you should look out for certain safety features to avoid injury. As a beginner seeking an electric or manual sharpening system, look out for non-skid rubber feet. If you are using a handheld device, ensure that it offers a secure grip.

What Level of Maintenance Does a Knife Sharpening System Require?

It requires continuous upkeep, because loading, which is the transfer of the knife’s steel to stone, can reduce the effectiveness of stones. Thus, it is important to find a system that fits the amount of time and effort you are willing to invest in its maintenance.

For instance, stones need to be cleaned, soaked, and flattened periodically, while the maintenance of electric machines can be more elaborate. After every use, electric machines must be unscrewed, its sharpening wheel removed, shaken upside down, and brushed thoroughly for debris. Understanding the energy you will put into a sharpening system’s maintenance will help you find a system that fits your lifestyle.

Conclusion

There is a myriad of other types of knife sharpeners and this article only covers a few of the most common ones. The sharpening system for you isn’t necessarily the one that provides the sharpest blade – after all, many of these sharpeners can all produce top-quality edges. Instead, in the end, the best knife sharpening system is the one that suits you and your needs the best, whether it be in price, portability, convenience, or efficiency. Hopefully, this article has provided you with some insight into picking a knife sharpener to keep your blades sharp and strong. Good luck!